This category involves procedures related to bones, joints, and musculoskeletal structures. Surgeons can use 3D-printed bone models to practice fracture reduction, joint replacement, and spinal procedures.

Read MoreSurgical

Planning

Patient-specific design and in-house manufacturing of customized medical devices.

At BRMR, these same advanced digital design and additive manufacturing capabilities are applied beyond simulation, supporting the in-house manufacturing of customized cranio-maxillofacial implants and surgical solutions. Our workflow allows surgeons to physically evaluate, plan, and rehearse procedures using lifelike models before transitioning seamlessly to the production of patient-specific medical devices intended for real clinical application.

Services

SURGERY SIMULATION

3D-printed models can replicate intricate details of the skull, brain, and spinal cord. Neurosurgeons can practice tumor removals, aneurysm clippings, and other delicate procedures.

Read MoreSurgeons in this field can use 3D-printed heart and lung models to simulate complex procedures like valve replacements, coronary artery bypass grafts (CABG), and congenital heart defect repairs.

Read MoreFor procedures involving blood vessels, such as aneurysm repairs or angioplasties, 3D-printed models can help surgeons practice device placement and understand vascular anatomy.

Read MoreProducts

Patient-Specific CMF PEEK Implants

Engineered for precise anatomical fit in cranio-maxillofacial reconstruction

BRMR provides patient-specific cranio-maxillofacial (CMF) implants manufactured from medical-grade PEEK. Each implant is designed from patient CT data, reviewed with the surgeon, and manufactured in-house to deliver a precise fit, controlled quality, and a clear workflow from planning to final device.

Medical-Grade PEEK Material

Non-metallic, radiolucent polymer selected for cranio-maxillofacial reconstruction

Polyetheretherketone (PEEK) is a high-performance medical polymer widely used in cranio-maxillofacial implants due to its bone-like mechanical behavior, radiolucency, and long-term stability. Its non-metallic nature allows clear post-operative imaging without artifacts, while supporting precise patient-specific design and manufacturing.

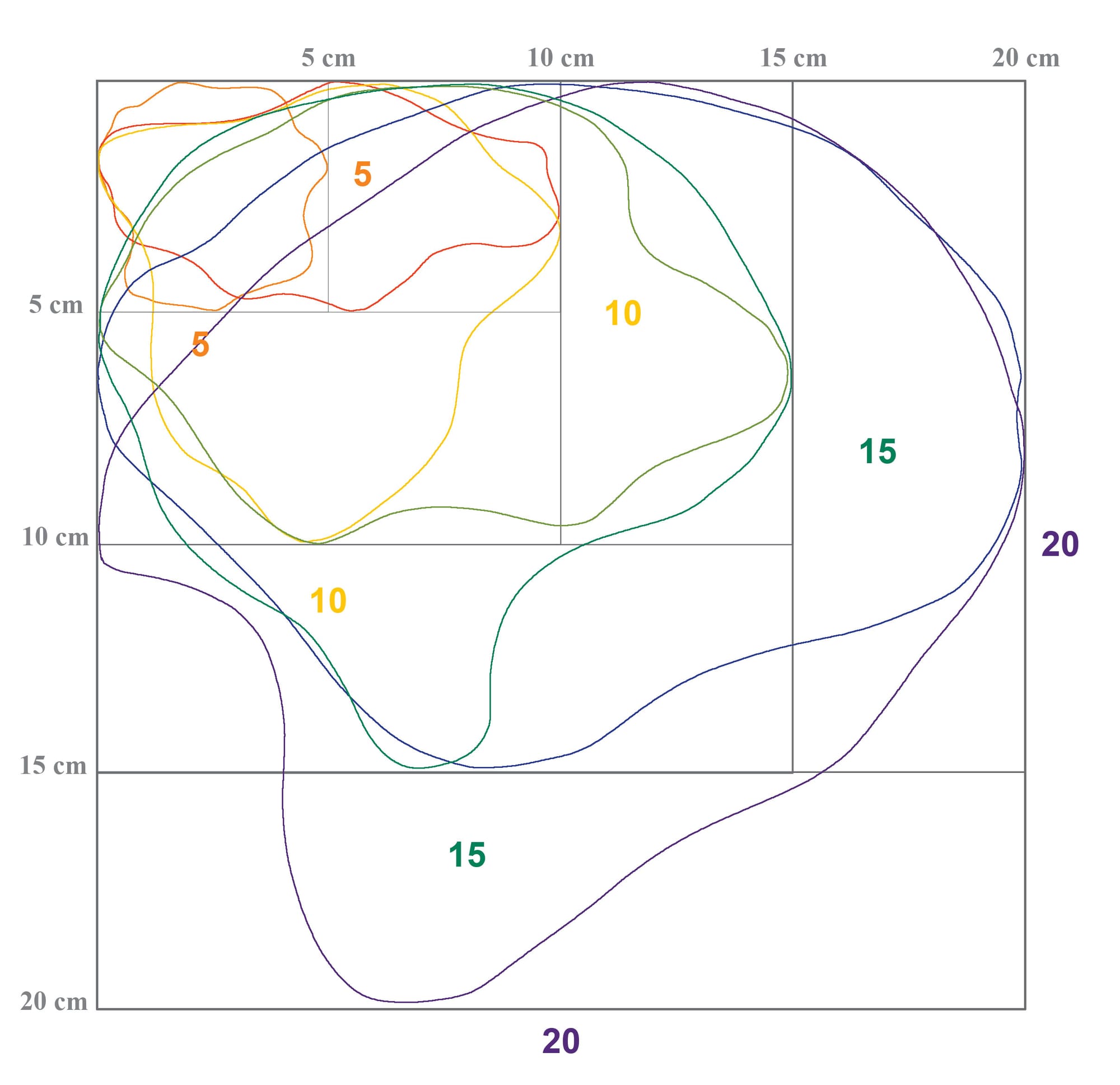

Elastic Modulus of Common CMF Implant Materials

Comparative stiffness values of human bone, medical-grade PEEK, and titanium

Human bone exhibits an elastic modulus in the range of approximately 3–5 GPa. Medical-grade PEEK has an elastic modulus of approximately 4 GPa, closely aligning with bone. In contrast, titanium demonstrates a substantially higher elastic modulus of approximately 110 GPa.

Design & Surgical Planning

Patient-specific digital workflow based on clinical imaging data

Each cranio-maxillofacial implant is designed using patient CT (DICOM) data to accurately reconstruct anatomical geometry and defect boundaries. The digital planning process enables precise implant contouring, preoperative evaluation, and surgeon review prior to manufacturing, ensuring alignment with clinical requirements and surgical approach.

Manufacturing Quality Control & ISO-Aligned

In-house production with controlled quality processes

Manufacturing is performed in-house under a controlled production workflow aligned with medical device quality management principles. Each patient-specific implant is produced according to an approved design, followed by defined post-processing, dimensional verification, and final inspection prior to release. Quality records, traceability, and case-specific documentation are maintained to support risk management, consistency, and regulatory compliance.

Licence

Order Placement

Submit case details for design review and manufacturing quotation

The price of each customized CMF PEEK implant is determined directly by its overall size and footprint. Larger defects require more PEEK material, longer print durations, higher annealing cycles, and extended post-processing and QC time. To keep the pricing transparent, the implant is measured across its maximum width and height; the implant is then placed into the corresponding size tier on the chart (5–20 cm). Each tier reflects the manufacturing effort, material consumption, machining precision, and regulatory-compliant workflow required for that scale. In short: the larger the implant, the higher the production demands, so the pricing follows the exact size category shown on the chart.

DESIGN FOR SOLUTION

Elevating Medical Excellence Through Innovative Design Solutions

Where the convergence of design ingenuity and medical science leads to a new paradigm of patient care. Our commitment to revolutionizing the medical field through cutting-edge design solutions is at the core of what we do.

Designing for Precision

In the realm of medicine, precision is paramount. Our tailored 3D design solutions empower surgeons to visualize and meticulously plan intricate procedures. From complex orthopedic interventions to delicate neurosurgical cases, our designs create a roadmap for success, ensuring optimal outcomes for each patient.

Personalization at its Finest

No two medical cases are identical, and neither are our design solutions. Embracing the uniqueness of every patient, we craft bespoke 3D models, implants, and tools that mirror the intricacies of individual anatomies. This personalization enhances surgical accuracy and fosters improved patient experiences.

Empowering Surgical Excellence

The marriage of cutting-edge design and medical expertise empowers surgeons to elevate their practices. With 3D-printed models and guides, they refine their techniques, validate surgical approaches, and ensure the highest standards of precision. This empowerment translates to better patient outcomes and minimized risks.

Shaping the Future of Healthcare

At BRMR Science, we're not just designing objects; we're shaping the future of healthcare. Our designs contribute to streamlined surgeries, reduced recovery times, and improved patient well-being. As we continue to innovate, the boundaries of what's possible in medical design are continually expanding.

Join the Design Revolution

Step into a new era of medical care with us. Witness how our innovative design solutions, powered by advanced 3D printing technology, are transforming the medical landscape. At BRMR , we're driven by the pursuit of excellence and the commitment to enhancing patient care through revolutionary design.

3D PRINT

Welcome to a new era of medical excellence

Welcome to BRMR Science

A herald of a new medical era. Merging cutting-edge technology with compassionate care, our pioneering 3D printing service redefines surgical precision and elevates patient outcomes, reshaping the medical landscape.

Why Choose BRMR Science?

Unleashing the Power of 3D Printing in Medicine:

Envision perfecting medical procedures with our advanced 3D printing. Across specialties like orthopedics and cardiovascular care, our tailored models, guides, and implants redefine surgical planning and execution, forging a new era of excellence.

Customized Solutions for Every Case

Individuality defines patients and their medical requirements. Our service exemplifies this by crafting intricate, patient-specific models with unmatched precision. Surgeons gain visual, practice, and procedural mastery, delivering bespoke optimal outcomes.

Elevated Precision, Reduced Risks

The precision offered by 3D-printed models is nothing short of revolutionary. Surgeons can navigate intricate procedures with a level of confidence never before possible. The result Reduced surgical risks, minimized complications, and accelerated recovery times.

Empowering Communication and Patient Understanding

Transparency and communication lie at the heart of our service. Our 3D-printed models provide tangible visuals that empower patients to understand their procedures better. Informed decisions are at the core of patient-centered care, and our technology ensures just that.

Pioneering Surgical Innovation

At BRMR Science, we're not just enhancing existing procedures; we're pushing the boundaries of medical innovation. Collaborating with surgeons, engineers, and medical professionals, we're developing customized implants, devices, and tools that drive the future of medicine.

Your Journey to Enhanced Care Starts Here

Join us in embracing the future of medical practice

Witness firsthand how our advanced 3D printing technology is shaping the way surgeries are planned, executed, and perfected. At BRMR Science, we're guided by a relentless pursuit of excellence, fueled by a passion for innovation and unwavering patient care.

collaboration

ADVANCING HEALTHCARE TOGETHER

Why Collaborate with BRMR Science?

1. Transformative Technology:

Partnering with us means leveraging cutting-edge 3D printing technology to elevate your medical practice. Our solutions empower surgeons, enhance patient experiences, and bring about innovations that can set your institution apart.

2. Tailored Solutions:

We understand that each medical case is unique. Our collaboration brings patient-specific 3D-printed models, surgical guides, and implants to your practice, ensuring precision and personalization that contribute to better results.

3. Expertise and Guidance:

With BRMR Science as your collaborator, you'll have access to our team of skilled professionals, engineers, and innovators. We're here to support your institution with technical expertise, training, and guidance.

4. Pioneer Patient Care:

By collaborating with us, you're aligning your institution with a leader in medical innovation. Together, we can redefine patient care, offering solutions that optimize surgical planning, minimize risks, and promote quicker recoveries.

5. Drive Research and Education:

Collaboration opens avenues for research and education. Explore new techniques, validate procedures, and contribute to medical knowledge, all while offering your patients the best in care.

Let's Collaborate:

Partnering with BRMR Science is a strategic move towards a future of excellence in healthcare. We're excited to work hand in hand with hospitals and clinic centers that share our commitment to innovation, precision, and patient well-being.

Join Us in Shaping Healthcare:

Become a part of our network of forward-thinking medical institutions. Collaborate with BRMR and redefine the possibilities of patient care. Contact us today to start a conversation about how we can create a meaningful impact, together.